Supply Chain Management (SCM) Definition and Concepts

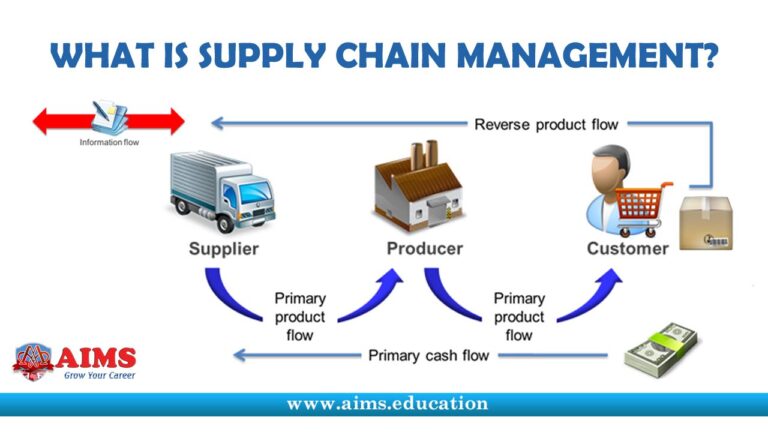

A Supply Chain (SC) refers to the network of organizations, people, activities, information, and resources involved in delivering a product or service to a consumer. It is a complex network of interconnected entities, processes, and activities that work collaboratively to deliver goods or services from the initial stages of production to the end consumer. Supply Chain Management (SCM) is a systematic and strategic approach to overseeing the entire process of producing and delivering goods or services from the initial stages of raw material acquisition through to the final delivery to the end consumer. It involves the coordination and integration of key business processes, functions, and activities across various entities within the supply chain network.

The key components of a Supply Chain include planning and strategy, procurement, manufacturing, logistics and delivery, and the management of returns and unsold inventory. Each stage in the supply chain is crucial, and effective coordination and integration are essential to optimize efficiency, reduce costs, and meet customer expectations. Information and material flows seamlessly through the supply chain, facilitated by communication, technology, and strategic decision-making. The primary objectives of supply chain management are to optimize efficiency, reduce costs, enhance product quality, and meet customer demands effectively.

Globalization has added further complexity, as supply chains often span multiple countries and involve diverse cultures, regulations, and logistical challenges. A well-managed supply chain not only ensures the timely delivery of products but also contributes to overall business success by enhancing competitiveness, mitigating risks, and fostering innovation and collaboration with suppliers and other stakeholders. In essence, a supply chain represents the intricate web of activities that transforms raw materials into finished products and delivers them to consumers, playing a pivotal role in the modern business landscape.

What Are The Different Stages of Supply Chain Management?

Supply chain management involves a series of interconnected stages that collectively ensure the efficient flow of goods and services from the initial production stage to the final consumer. The first stage is procurement, where raw materials or components are sourced from suppliers.

This is followed by manufacturing or production, where these inputs are transformed into finished products. Once the products are ready, the next stage is distribution, where they are transported and stored in warehouses before reaching retailers or end-users.

The logistics stage involves coordinating transportation, inventory management, and order fulfillment to optimize the movement of goods. Post-sales service and support represent the final stage, where customer feedback is collected, and any necessary returns or repairs are addressed.

Effective supply chain management requires seamless integration and collaboration across these stages to enhance efficiency, reduce costs, and meet customer expectations. Each stage plays a crucial role in the overall supply chain, and continuous improvement and adaptation are essential to navigate the complexities of modern global business environments. Lets briefly discuss each of the Stages.

Planning and Strategy for effective Supply Chain Management

The planning and strategy stage is the cornerstone of effective supply chain management. It involves setting the overall goals and objectives for the supply chain, considering factors such as market demand, production capacities, and resource availability. Strategic decisions made during this stage shape the entire supply chain process. This includes determining the optimal production levels, identifying potential risks, and establishing key performance indicators (KPIs) to measure success. Planning and strategy also involve forecasting demand, which helps in aligning procurement, manufacturing, and logistics activities. By developing a robust plan and strategy, organizations can proactively address challenges, allocate resources efficiently, and enhance overall supply chain resilience.

Procurement or Sourcing:

Procurement or sourcing is the stage where raw materials, components, or finished goods are acquired from suppliers. This process involves selecting the right suppliers, negotiating contracts, and ensuring a reliable and cost-effective supply of materials. Strategic decisions made during procurement impact product quality, production costs, and overall supply chain efficiency. Organizations need to build strong relationships with suppliers, assess their capabilities, and implement sustainable sourcing practices. Effective procurement also involves risk management strategies to mitigate potential disruptions in the supply chain. By optimizing the procurement process, organizations can achieve cost savings, maintain product quality, and foster long-term partnerships with suppliers.

Manufacturing :

The manufacturing stage is where raw materials or components are transformed into finished products. It encompasses various processes such as production planning, quality control, and efficient utilization of resources. Manufacturers strive to achieve economies of scale, minimize production lead times, and enhance product quality. Technology plays a crucial role in modern manufacturing, with automation and data analytics improving efficiency and accuracy. Lean manufacturing principles, such as just-in-time production, aim to reduce waste and optimize the production process. Effective communication and collaboration between different departments within the organization are essential to ensure a smooth manufacturing process that aligns with overall supply chain goals. All the activities in this Stage are supervised by Supply Chain Managers.

Logistics and Delivery: Key Role in Supply Chain Management

Logistics and delivery involve the physical movement of goods from the manufacturing facility to the end consumer. This stage encompasses transportation, warehousing, and distribution processes. Efficient logistics management is critical for minimizing lead times, reducing transportation costs, and ensuring timely delivery to meet customer demands. Technologies like GPS tracking, route optimization, and real-time visibility enable organizations to streamline logistics operations. Warehousing plays a vital role in inventory management and order fulfillment. Collaborative relationships with transportation providers and accurate demand forecasting contribute to effective logistics and delivery, ultimately enhancing customer satisfaction and loyalty.

Managing Returns & Unsold Inventory:

The final stage in the supply chain is managing returns and handling unsold inventory. This includes the return of Faulty or Damaged Products by the Customers. Needless to say this is a huge concern for lot of Retailers (like Walmart, Amazon) where Return Management or Unsold Inventory remains a Huge Challenge to address. This aspect has gained prominence as customer expectations for flexible return policies have increased.

Efficient management of returns involves processes for inspecting, refurbishing, recycling, or disposing of returned products. It is crucial to strike a balance between satisfying customer needs and minimizing the financial impact of returns. Additionally, dealing with unsold inventory requires strategies such as discounting, repurposing, or liquidation.

Technologies like reverse logistics systems and analytics help organizations optimize their approach to managing returns and unsold inventory, ensuring that they minimize losses and environmental impact while maintaining customer satisfaction. This stage reflects the importance of a closed-loop supply chain, where products are managed throughout their entire lifecycle, from production to end-of-life considerations.

Supply Chain Management Explained in a Video :

The Video Explains all the related concepts in a Supply Chain (SC) Network. Watch the Supply Chain (SC) Learning Videos to understand the terms, definitions and examples related to Supply Chain (SC)

Topics in the Video :

- A Global Network

- A Basic Supply Chain: Seller, Producer, Customer

- Strategies: Stable, Reactive, Efficient-Reactive

- Flows in Supply Chains

- Corporate Supply Chain Model

- Supply Chain in Services

- Supply Chain Management: Vertical and Horizontal Integration

- Benefits of Vertical and Horizontal Integration

- Stages of Supply Chain Management Evolution

- What is Supply Chain Management?

The Video below by W.P. Carey School of Business describes the complex Supply Chain (SC) of a simple product, a bottle of water. The video also illustrates the importance of supply chain managers and their skill sets in our modern global economy for both manufacturing and service industries. In defining Supply Chain Management (SCM), the video also hopes to educate and inspire business students, young and old, about the opportunities available to those with supply chain management degrees.

Supply Chain (SC) Simplified with an Example of Water Bottle

The ubiquitous water bottle, a seemingly simple commodity, conceals a labyrinthine journey through a comprehensive and intricate supply chain. This Topic delves into the multifaceted process that transforms raw materials into the familiar vessel that quenches our thirst. From the initial extraction of resources to the hands of the consumer, each stage in the supply chain plays a vital role, involving various stakeholders, technologies, and logistical considerations.

Supply Chain Management of a Water Bottle:

Raw Material Extraction

The journey of a water bottle begins with the extraction of raw materials, typically polyethylene terephthalate (PET) for the bottle itself and high-density polyethylene (HDPE) for the cap. PET, derived from crude oil, undergoes a refining process to create the polymer used in bottle production. The HDPE cap may also originate from petroleum or natural gas. Sustainable practices, such as recycling or the use of bio-based materials, are increasingly integrated into this stage to address environmental concerns.

Manufacturing and Preform Production

Once the raw materials are obtained, they undergo a meticulous manufacturing process. PET pellets are heated and molded into preforms, the intermediate stage before forming the actual bottle. These preforms are then transported to the bottling facility. The production process involves injection molding machines, which shape the preforms into the iconic bottle design. The caps undergo a similar process, with HDPE molded into cap shapes.

Bottling and Filling

At the bottling facility, the preforms are subjected to a two-step process known as stretch blow molding, where they are inflated and stretched into the final bottle shape. Simultaneously, the caps are produced and assembled. The bottles are then thoroughly cleaned and sanitized before being filled with water. This stage involves precision and adherence to quality control standards to ensure the purity and safety of the bottled water.

Labeling and Packaging

Following the filling process, bottles move to the labeling and packaging stage. Labels, often made from materials like polypropylene, are affixed to the bottles. Automated systems streamline this process, ensuring accuracy and efficiency. Once labeled, the bottles are packaged in groups, often in shrink-wrapped plastic or cardboard, for efficient transportation to distribution centers.

Distribution and Logistics

Distribution is a critical link in the water bottle supply chain. Distribution centers strategically located across regions receive bulk shipments and act as hubs for further transportation. Logistic considerations such as route optimization, transportation modes (trucks, ships, or railways), and inventory management are meticulously planned to minimize costs and maximize efficiency. Real-time tracking technologies play a crucial role in ensuring the timely and secure movement of water bottles from manufacturers to retailers.

Retail Placement

Upon reaching regional distribution centers, water bottles are then transported to various retail outlets. Whether it’s supermarkets, convenience stores, or gas stations, the placement of water bottles on shelves requires collaboration between manufacturers, distributors, and retailers. Shelf space, promotional displays, and marketing strategies all contribute to the visibility and accessibility of bottled water for consumers.

Consumer Purchase and Post-Sales

The final stage of the water bottle supply chain occurs when consumers make a purchase. Post-sales aspects, such as product recalls, customer feedback, and potential returns, are managed through integrated systems. Advances in technology enable traceability, allowing manufacturers to monitor and respond to consumer preferences and concerns.

Environmental Considerations and Recycling

In recent years, the environmental impact of plastic bottles has spurred increased attention on recycling efforts. Many water bottle manufacturers have incorporated recycled PET (rPET) into their production processes, contributing to a circular economy. Recycling initiatives, such as deposit systems and awareness campaigns, aim to mitigate the environmental impact of plastic bottles by encouraging responsible disposal and recycling practices.

Conclusion

The journey of a water bottle from source to sip is a testament to the complexity and interconnectedness of modern supply chains. The seamless orchestration of various stages involves the collaboration of numerous stakeholders, from raw material suppliers to retailers. As consumers, understanding this intricate process empowers us to make informed choices about the products we use, fostering a greater appreciation for the intricate dance of the supply chain that delivers the humble water bottle into our hands.

Learn more: